Our machines are engineered for low pressure molding applications. Using specialty resins to encapsulate delicate parts. Applications including : automotive electronics, PCBA,coil, fiber-optic, LED lighting, wire, cable, etc.

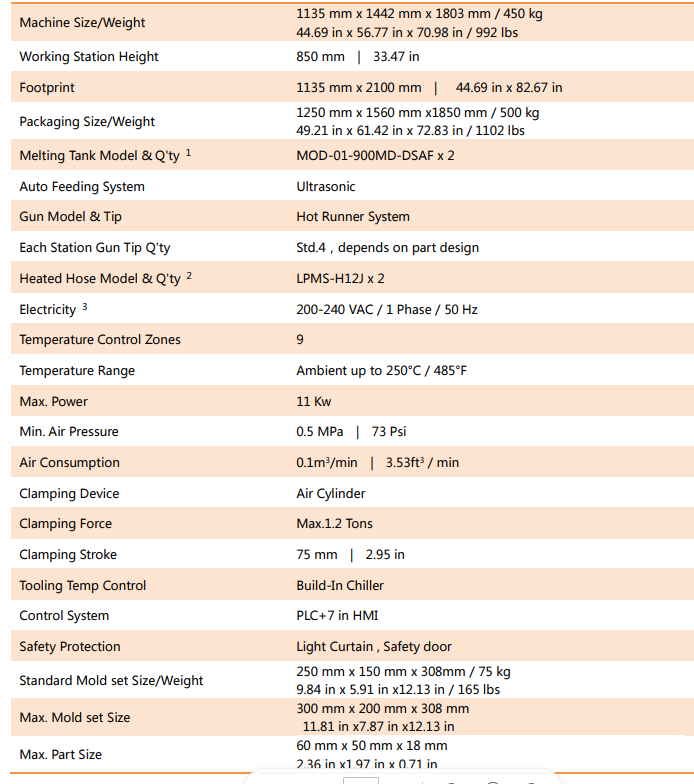

- Turntable design. One upper mold serves two bottom molds.

- Melt-on-Demand technology helps resin melt down completely within 8-15 minutes (measure based on resin softening temperature at 100~160 °C).

- Equipped with dual 1 liter melting tanks to fit different color resin or different model resin.

- Hot runner system eliminates runner resin and improve productivity.

- Built-in chiller.

- Injection pressure is controlled by proportional electromagnetic valve and it can be adjusted by the touch screen precisely.

- Temp in different temp zones like tank, hose, hot runner, hot nozzles can be set independently.

- Automatic feeding system and ejection system is equipped

Schedule A Free Consultation

We’re happy to answer any questions you may have and help you determine which of our services best fit your needs.

TEL : 607-861 6871