Our machines are engineered for low pressure molding applications. Using specialty resins to encapsulate delicate parts. Applications including : automotive electronics, PCBA,coil, fiber-optic, LED lighting, wire, cable, etc.

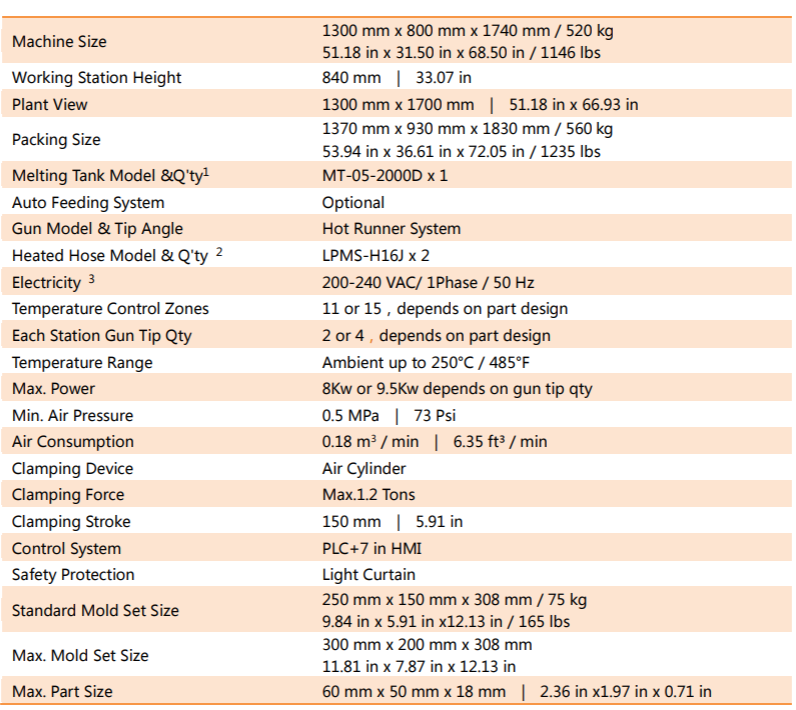

- Dual independent working stations.

- Hot runner system eliminates runner resin and improve productivity.

- 5 liter melting tank and machine is separate. Multiple melting tank is optional.

- User-friendly interface, 7″ Touch screen operator with multi-language PLC.

- Fifteen thermal control zones for precise melt control.

- Equipped with light curtain and dual palm buttons for operator safety.

- Mechanical ejection system and control for pneumatic ejection.

Schedule A Free Consultation

We’re happy to answer any questions you may have and help you determine which of our services best fit your needs.

TEL : 607-861 6871