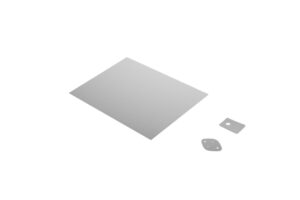

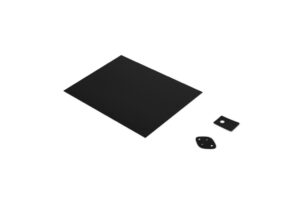

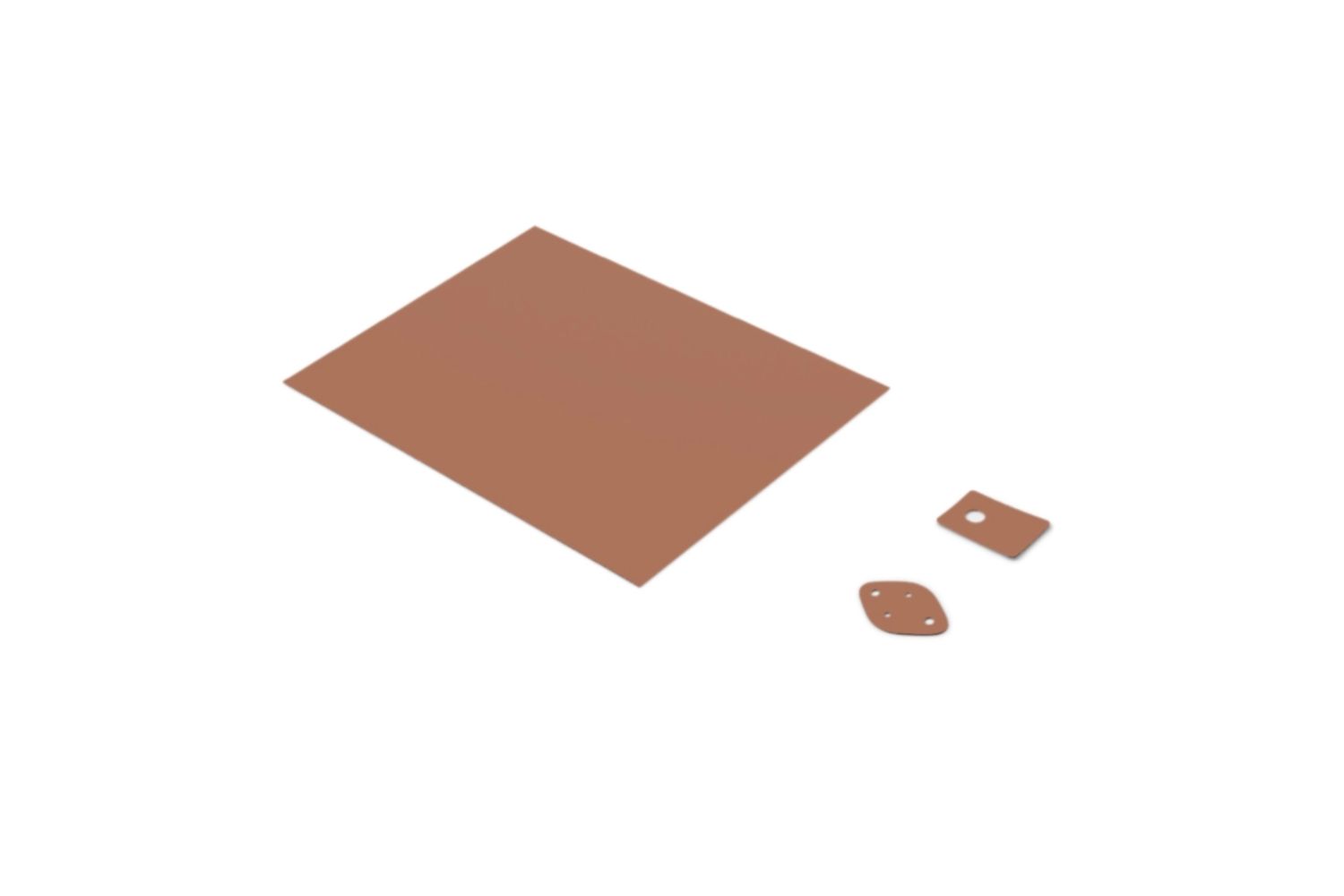

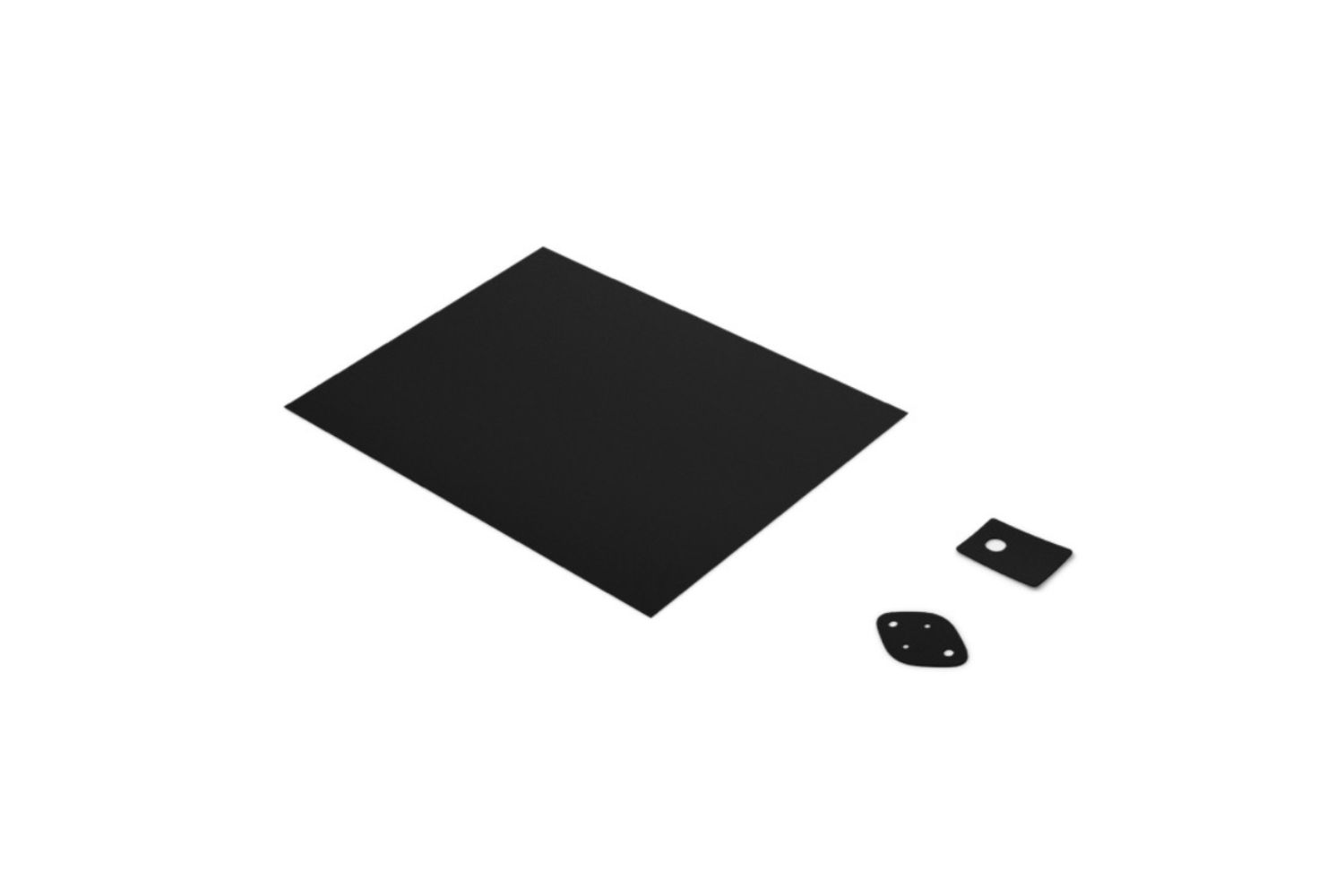

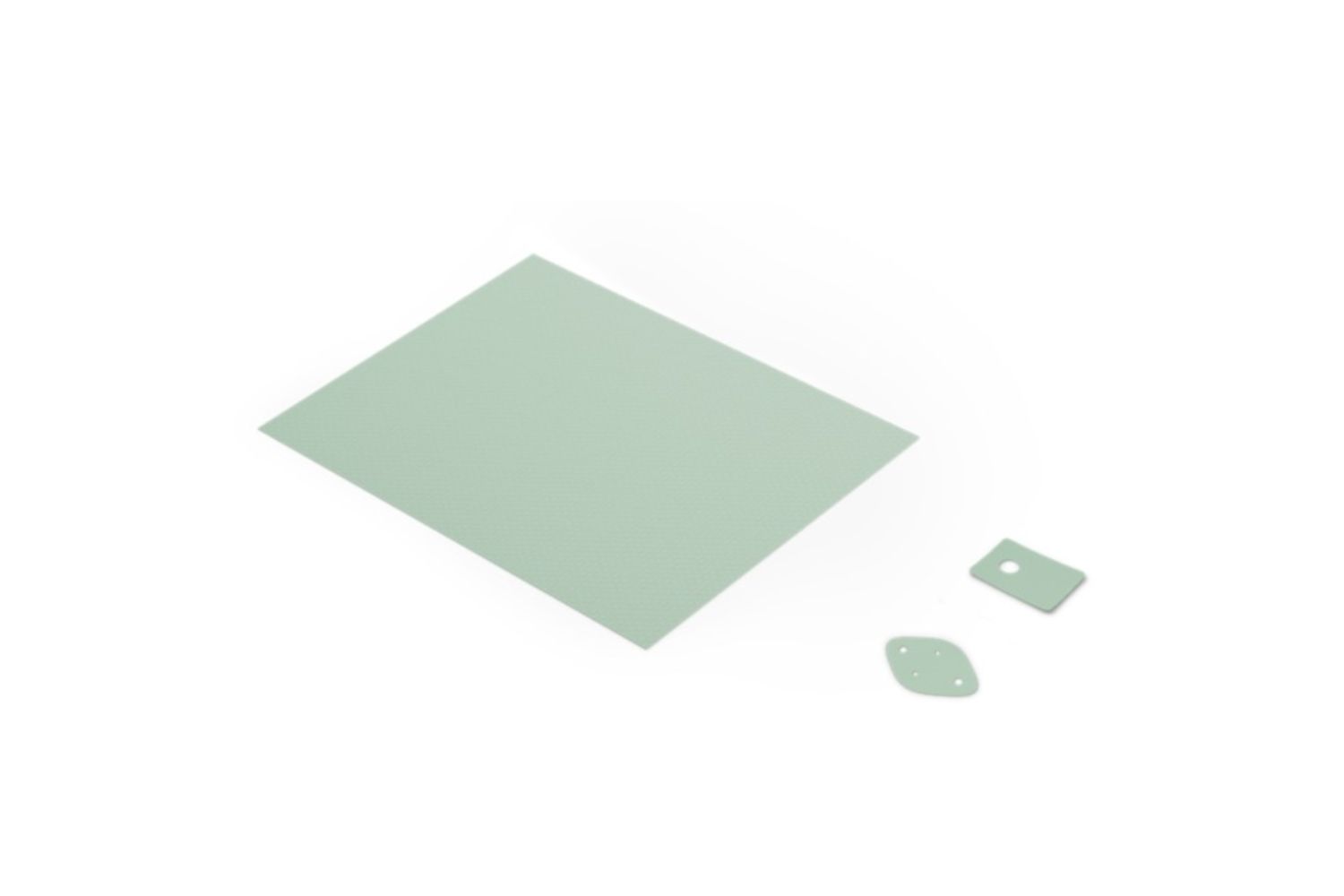

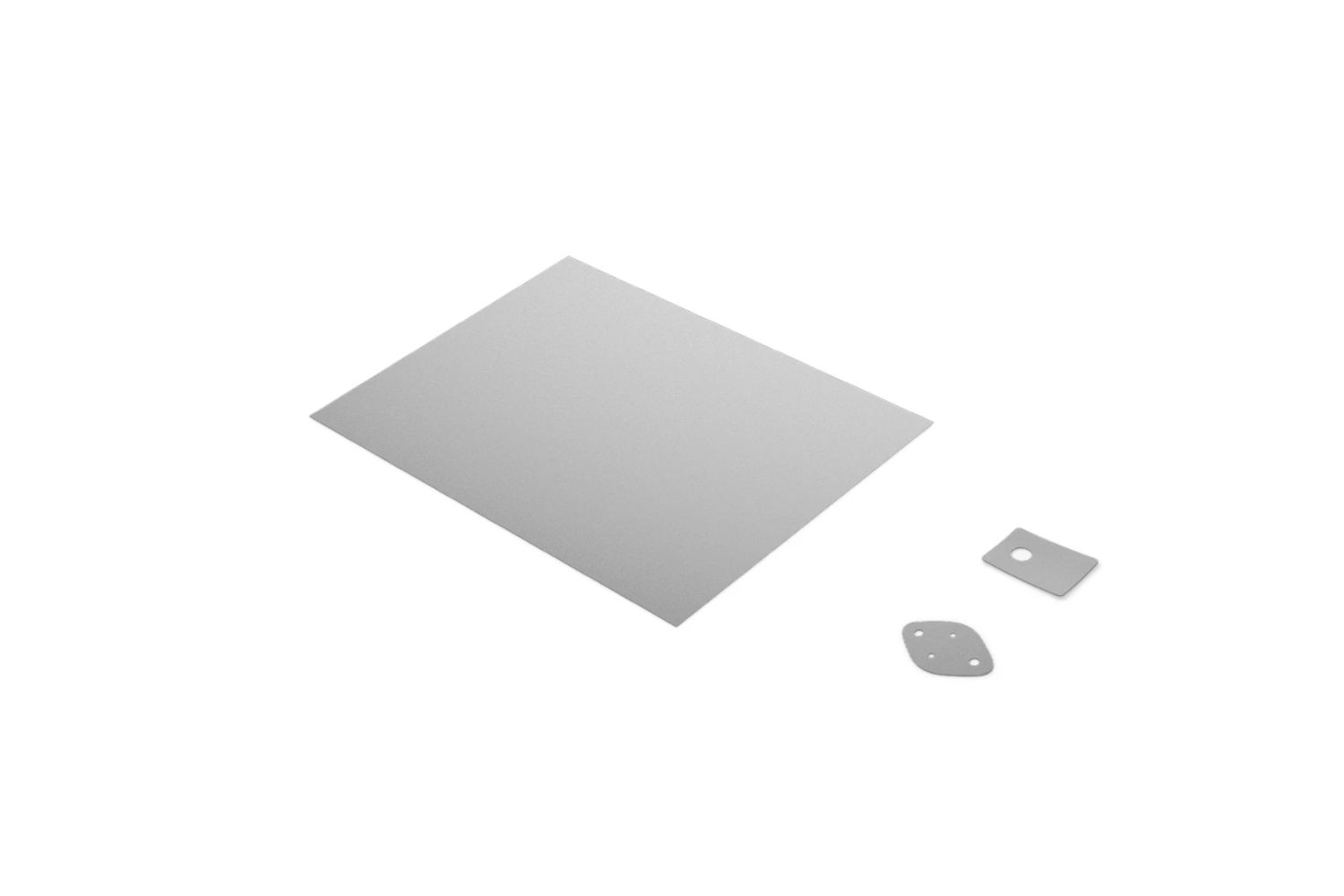

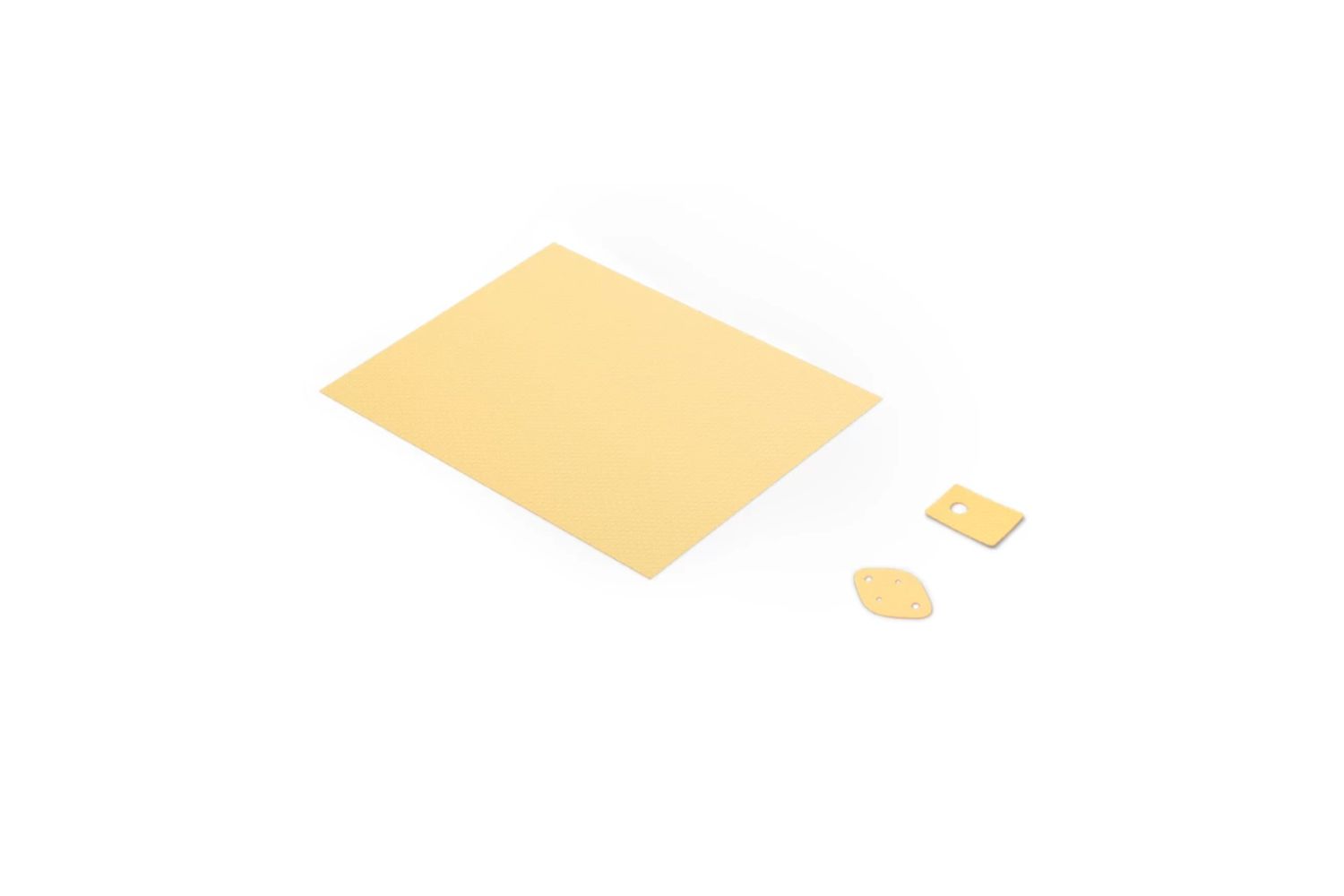

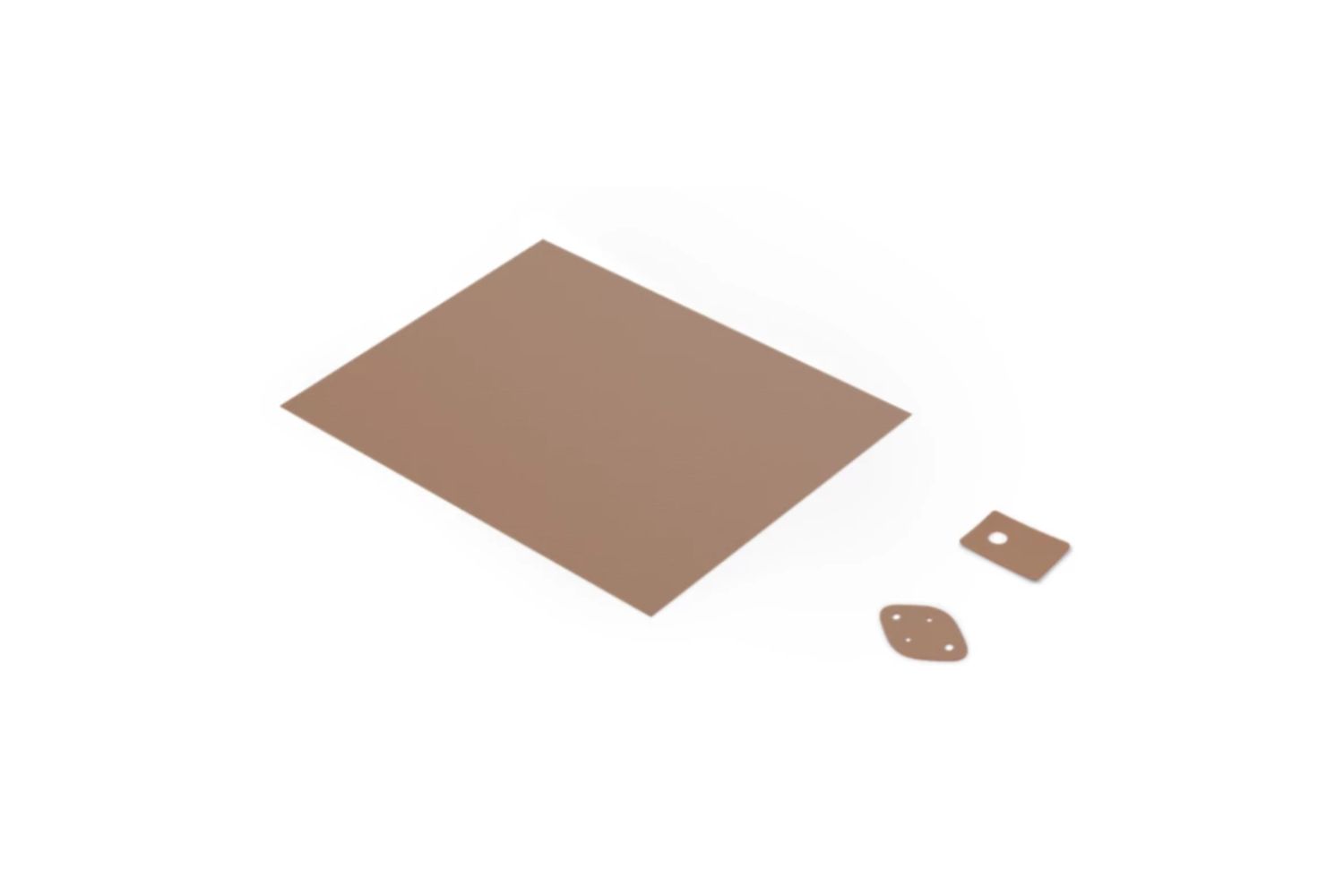

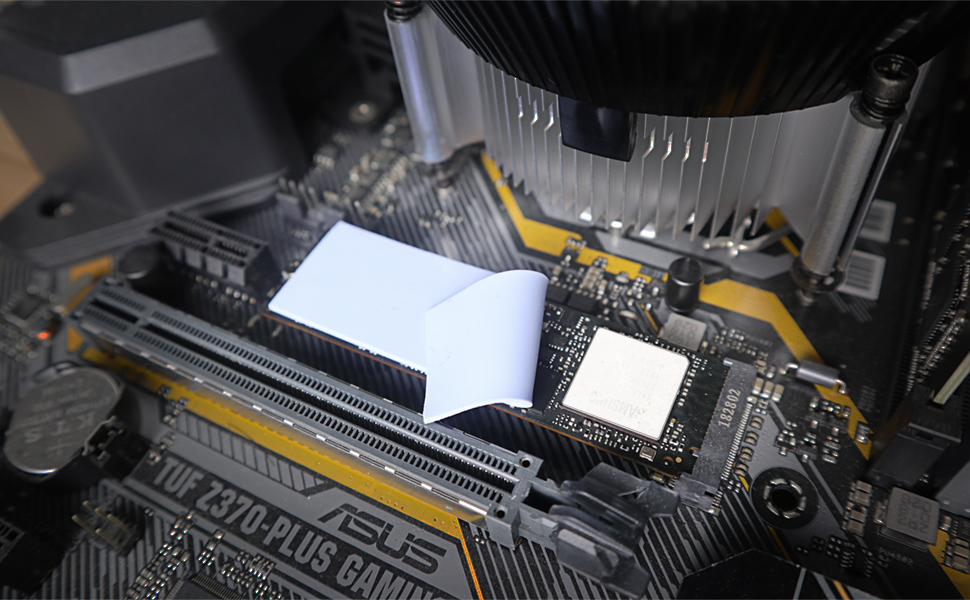

Thermal Interface Material

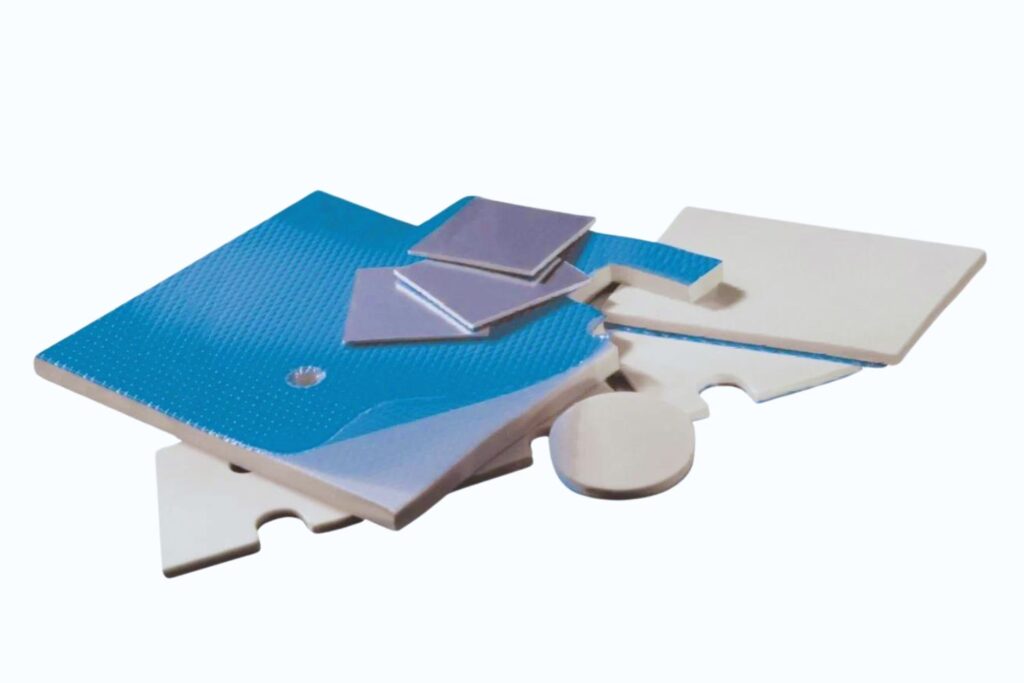

Our Die Cutting Service, coupled with Thermal Interface Material (TIM), is a specialized solution designed to optimize heat transfer in various applications.

" Our Thermal Interface Material (TIM) die-cut service offers precision and customization for your thermal management needs in any shape you want. "

Efficient Heat Transfer

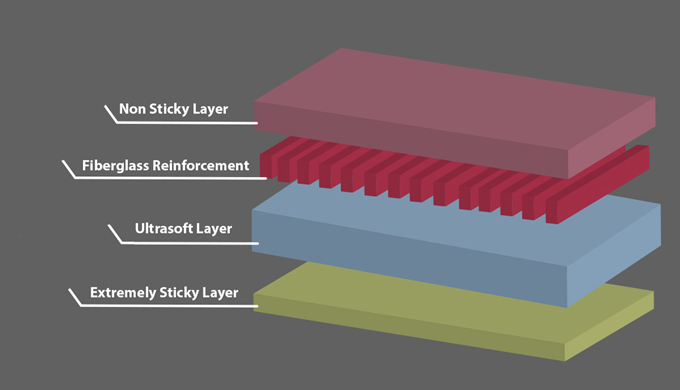

The primary function of TIM is to enhance the efficiency of heat transfer between two surfaces. It fills microscopic gaps and irregularities between the surfaces, ensuring a more direct and efficient thermal conduction path.

Reduced Thermal Resistance

TIM significantly reduces thermal resistance at the interface between heat-generating components (such as processors or electronic devices) and heat sinks or other cooling solutions. This helps in dissipating heat more effectively, preventing overheating and potential damage.

Improved Thermal Performance

By minimizing thermal resistance, TIM improves the overall thermal performance of electronic components. This is crucial in applications where maintaining optimal operating temperatures is essential for performance, reliability, and longevity.

Enhanced Reliability

TIM helps prevent overheating, which can lead to performance degradation and component failure. By maintaining lower operating temperatures, electronic devices and components experience improved reliability and a longer operational life.

Versatility in Applications

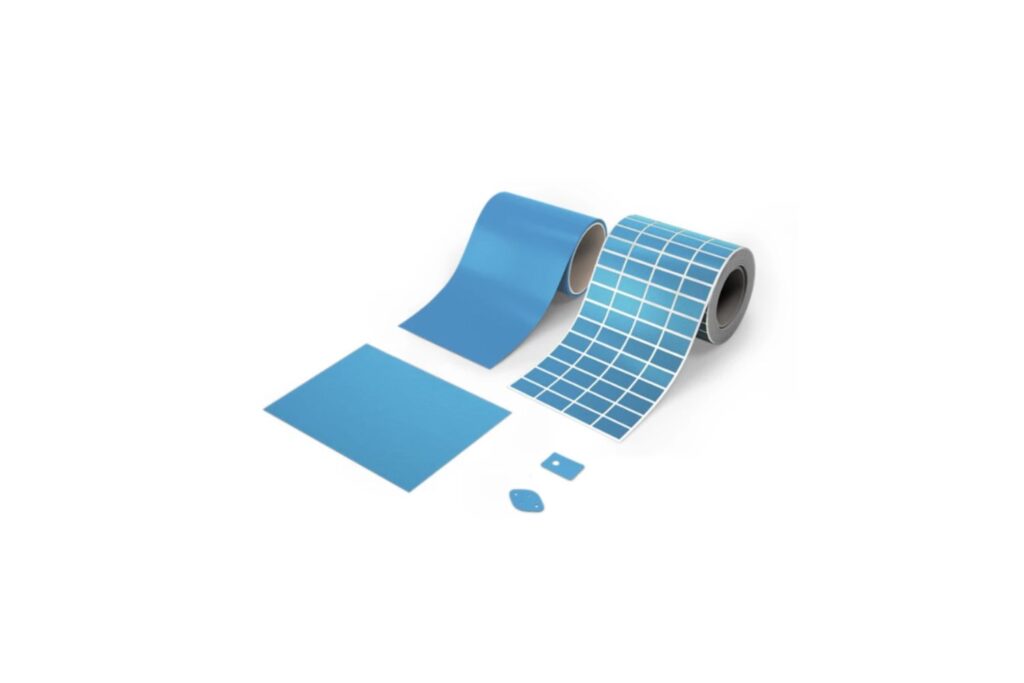

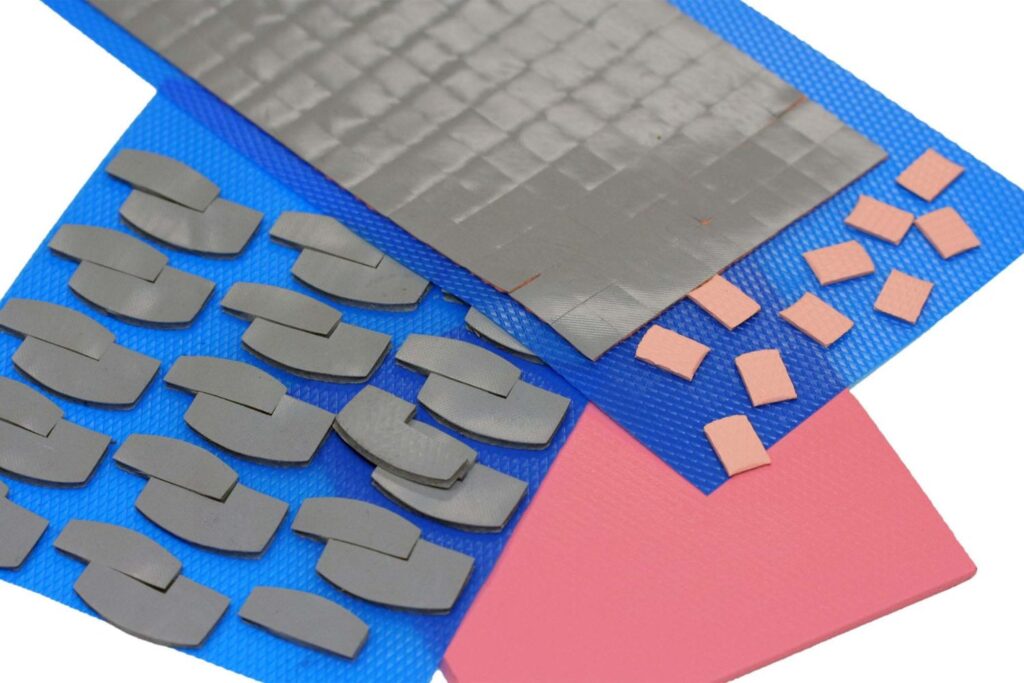

TIM is versatile and applicable in various industries, including electronics, automotive, aerospace, and more. Its adaptability allows it to be used in different forms, such as films, pads, or pastes, making it suitable for diverse applications and configurations.

Ease of Application

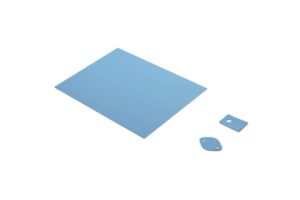

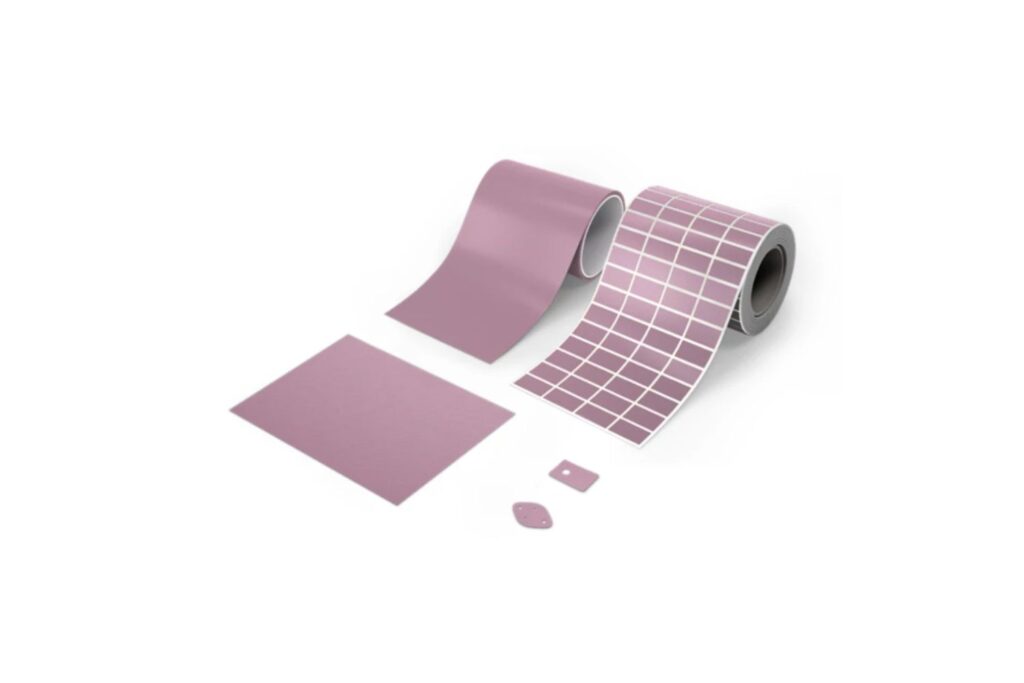

The die-cutting process facilitates the precise application of TIM to specific areas, ensuring optimal coverage and minimal waste. This precision is particularly valuable in electronic devices with limited space or complex configurations.

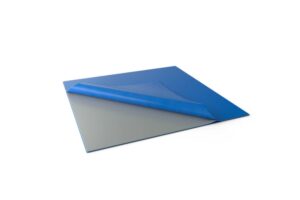

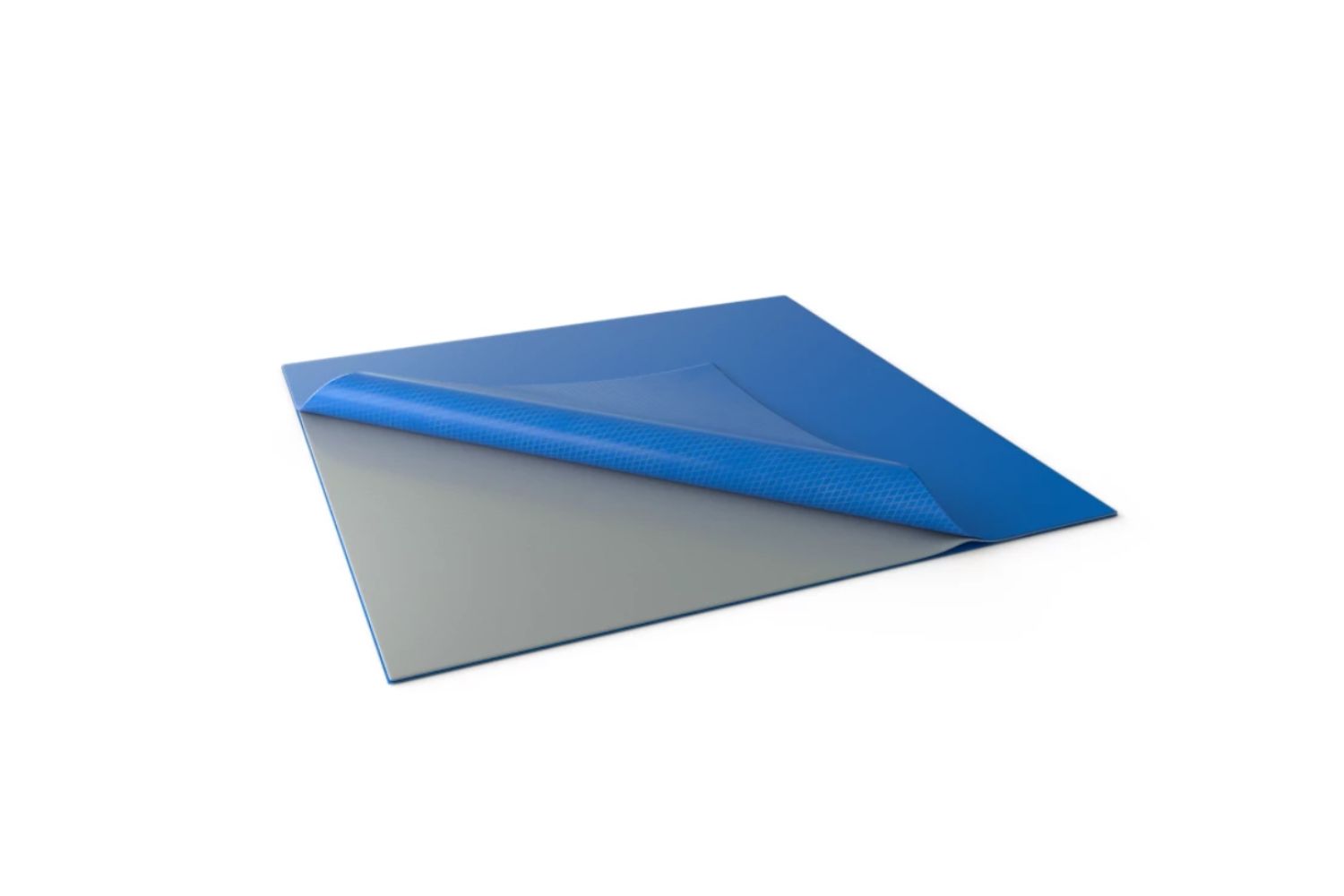

Henkel's Bergquist offers Thermal Interface Materials (TIMs) for effective thermal management in application design.Auzana specializes in die-cutting these materials into finished thermal pads, catering to various applications. Two main types include Gap Filling Pads (thicker, .015" - .250") offering thermal conductivity without much pressure, and Thin Thermal Pads (.030" - .005") requiring pressure for sustainable pressure and reduced thermal impedance. These solutions address the diverse thermal challenges in modern applications.

Enquiry to process

The following chart will illustrate the general process of our screw patching service.

1. Inquiry

Initiate the process with a customer inquiry, understanding the specifications and requirements for the Thermal Interface Material (TIM).

2. Material Selection

Engage in consultations to select the appropriate TIM, considering factors like thermal conductivity and application-specific needs. Customize the die-cutting process accordingly.

3. Prototype and Testing

Develop a prototype to validate specifications and conduct rigorous testing for quality assurance before full-scale production.

4. Production Planning

Plan the production process, determining batch sizes, lead times, and resource allocation for efficient manufacturing.

5. Die Cutting and Finishing

Employ specialized equipment to precisely cut the TIM into specified shapes and sizes. Implement post-cutting treatments as needed for cleaning or surface modifications.

6. Quality Check and Packaging

Inspect the die-cut TIM for quality, ensuring uniformity and accuracy. Package the final product securely for delivery, meeting project timelines and customer expectations.

RELATED PRODUCT

Our Thermal Interface Material (TIM) application process is a precision-focused and specialized service crafted to enhance thermal management, guaranteeing optimal heat dissipation and performance reliability for your equipment.